IntruductionStable floor decking is made from recyclable wood flour, hdpe and distinctive components. in comparison with the wpc strong decking, the hollow one is lighter and cheaper. also it could gift the particular colours and the specific fashion. the set up may be rapid and easy. it’s entire call is timber plastic composite decking(wpc decking). and it performs with its notable water resistance, specially suitable to be used in a moist surroundings.

Contact Now

IntruductionThe second purpose of wood plastic flooring is the decoration or creative construction of landscape walls and buildings.

Contact Now

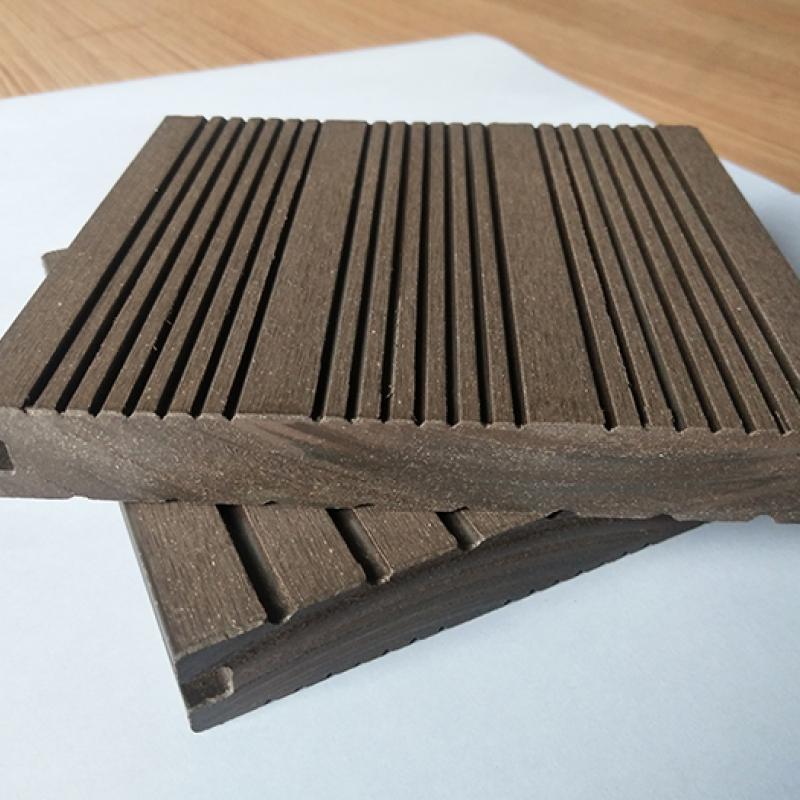

IntruductionHollow WPC decking is made from recyclable wood flour, HDPE and other additives. Compared with the WPC solid decking, the hollow one is lighter and cheaper. Also it could present the different colors and the different style. The installation could be fast and easy. It’s complete name is Wood plastic composite decking(WPC Decking). And it performs with its excellent water resistance, especially suitable for use in a humid environment.

Contact Now

IntruductionHollow WPC decking is made from recyclable wood flour, hdpe and extraordinary components. in evaluation with the wpc strong decking, the hollow one is lighter and less costly. also it can gift the only of a kind colours and the extremely good style. the set up may be fast and clean. it’s whole name is wooden plastic composite decking(wpc decking). and it performs with its awesome water resistance, particularly suitable for use in a damp surroundings.

Contact Now

Before the floor decking installed, the WPC joists shall be stored in the condition of temperature of 20±2 °C for at least one day if they were previously kept at a temperature between 0 °C and 10 °C and for at least 48 hours if they were previously stored at a temperature below 0 °C. The distance between fixed points and ends (walls, skirting boards, etc.) and the final ends of the decking joists shall be at least 10 mm.The gap between the decking joists shall not exceed 350 mm (along the axes of the decking joists).

Contact Now

Basic DescriptionNameHollow Wood-plastic Composite Floor DeckingSerial NumberVariousMaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecificationVariousColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationHollowApplication:OutdoorCustomized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Southeast Asia,Central Asia,Europe & North AmericaHS Code3918909000Lead Time:15 Days for 1X20 GP ContainerTransport Package:Pallet ,Stretch Film,fluting paper (for whole container)AdvantagesWear-resistingWater-proofDam-proofFireproofNo-pollutio

Contact Now

Solid Floor DeckingSolid WPC decking is made from recyclable wood flour, HDPE and other additives.So, wood plastic composite decking is a new type environmentally friendly composite profile. This kind composite materials is produced in the production granulation and extrusion equipment and mould. Compared with the WPC solid wooden decking, the WPC solid one is stronger and cheaper. Also it could present the different colors and the different style. The installation could be fast and easy. It’s complete name is Wood plastic composite decking(WPC Decking).

Contact Now

Advantages:1.Outdoor hollow floor decking present its natural wood feeling and texture style.2.It could be easily installed and uninstalled in simple way and equipment.3.This material is100% recycled and Eco-friendly.4.WPC composite outdoor decking needs low maintenance and no paint,stain or oil.But it could hold the paint.

Contact Now

IntruductionStable floor decking is made from recyclable wood flour, hdpe and distinctive components. in comparison with the wpc strong decking, the hollow one is lighter and cheaper. also it could gift the particular colours and the specific fashion. the set up may be rapid and easy. it’s entire call is timber plastic composite decking(wpc decking). and it performs with its notable water resistance, specially suitable to be used in a moist surroundings.

Contact Now

Basic DescriptionNameWood-plastic floorSerial NumberVariousMaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecificationVariousColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationHollow and SolidApplication:Outdoor,Customized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Southeast Asia,Central Asia,Europe & North AmericaHS Code3918909000Lead Time:15 Days for 1X20 GP ContainerTransport Package:Pallet ,Stretch Film,fluting paper (for whole container)AdvantagesWear-resistingWater-proofDam-proofFireproofNo-pollutionEnvironmental

Contact Now

Basic DescriptionNameWood-plastic floorSerial NumberVariousMaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecificationVariousColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationHollowApplication:OutdoorCustomized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Southeast Asia,Central Asia,Europe & North AmericaHS Code3918909000Lead Time:15 Days for 1X20 GP ContainerTransport Package:Pallet ,Stretch Film,fluting paper (for whole container)AdvantagesWear-resistingWater-proofDam-proofFireproofNo-pollutionEnvironmental FriendlyIn

Contact Now

Basic DescriptionNameWood-plastic floorSerial NumberVariousMaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecificationVariousColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationSolidApplication:OutdoorCustomized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Southeast Asia,Central Asia,Europe & North AmericaHS Code3918909000Lead Time:15 Days for 1X20 GP ContainerTransport Package:Pallet ,Stretch Film,fluting paper (for whole container)AdvantagesWear-resistingWater-proofDam-proofFireproofNo-pollutionEnvironmental FriendlyIns

Contact Now

Basic DescriptionNameWood-plastic square tube Serial NumberVariousMaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecificationVariousColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationHollow and SolidApplication:Outdoor,Customized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Southeast Asia,Central Asia,Europe & North AmericaHS Code3918909000Lead Time:15 Days for 1X20 GP ContainerTransport Package:Pallet ,Stretch Film,fluting paper (for whole container)AdvantagesWear-resistingWater-proofDam-proofFireproofNo-pollu

Contact Now

Composite flooringLooking for the perfect composite floor for your project may be a torture. Selecting one of the co-extrution flooring decking options that could best suit your style and space is a joyful selecting process. We pride ourselves on manufacturing the best composite flooring services. Our composite decking floors will provide the suitable choice for you and it will last for generations.

Contact Now

IntruductionStable floor decking is made from recyclable wood flour, hdpe and distinctive components. in comparison with the wpc strong decking, the hollow one is lighter and cheaper. also it could gift the particular colours and the specific fashion. the set up may be rapid and easy. it’s entire call is timber plastic composite decking(wpc decking). and it performs with its notable water resistance, specially suitable to be used in a moist surroundings.

Contact Now

IntruductionThe first use is plastic wood flooring, which is connected with the base surface with matching screws and buckles. The floor is arranged and spliced into a whole piece of wood plastic flooring in order.

Contact Now

what is your delivery time?The time of delivery is winthin 15days after we receive the advance deposit.What is the shipping port? We ship the goods via Qingdao port. What is your payment terms?We accept 30% T/T in advance,70% in the period of shipment. Are you manufacturer?Our factory is located in the historical production base of China-Shandong. What are your main products?

Contact Now

Basic DescriptionNameWood-plastic floorSerial NumberVariousMaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecificationVariousColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationSolidApplication:OutdoorCustomized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Southeast Asia,Central Asia,Europe & North AmericaHS Code3918909000Lead Time:15 Days for 1X20 GP ContainerTransport Package:Pallet ,Stretch Film,fluting paper (for whole container)AdvantagesWear-resistingWater-proofDam-proofFireproofNo-pollutionEnvironmental FriendlyIns

Contact Now

Normal Colors ( Special Color Customized)Vivid Cases:Packing & Shipping: Package mainly the wooden pallet or the metal pallet. They are seaworthy and save the container space.

Contact Now

Specifications/Size: 1000mm×850mm, special design approvedNormal Colors as Shown and Customized Color approvedConstituent Parts and the Installation:WPC Box installation is simple:1.The first is to make the design and the basic frame2.The second is to cut the profiles into suitable length and shape.3.The third is to fix the WPC profiles decking onto the position of the design ot the frame.4.In the final, use the WPC edge board or the DIY boards to decorate the whole WPC Flower Box.We could supply the installation accessories and guide instruction. Packing & Shipping:Package mainl

Contact Now

Wood finish of our WPC railing provides a choice of desirable, tough anti-slip surface. The vivid wood grain look makes it more natural to see and feel. The boards have self-cleaning anti mildew construction and require virtually no maintenance for their life.Also it is easy intallation and cost efficiency.

Contact Now

Basic DescriptionNameWood-plastic floorSerial NumberVariousMaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecificationVariousColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationSolidApplication:OutdoorCustomized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Southeast Asia,Central Asia,Europe & North AmericaHS Code3918909000Lead Time:15 Days for 1X20 GP ContainerTransport Package:Pallet ,Stretch Film,fluting paper (for whole container)AdvantagesWear-resistingWater-proofDam-proofFireproofNo-pollutionEnvironmental FriendlyIns

Contact Now

IntruductionSolid Floor Decking is made from recyclable wooden flour, HDPE and different additives. Compared with the WPC strong decking, the hollow one is lighter and cheaper. Also it can gift the specific colorations and the specific style. The installation can be speedy and easy. It’s entire call is Wood plastic composite decking(WPC Decking). And it plays with its top notch water resistance, particularly appropriate to be used in a damp environment.

Contact Now